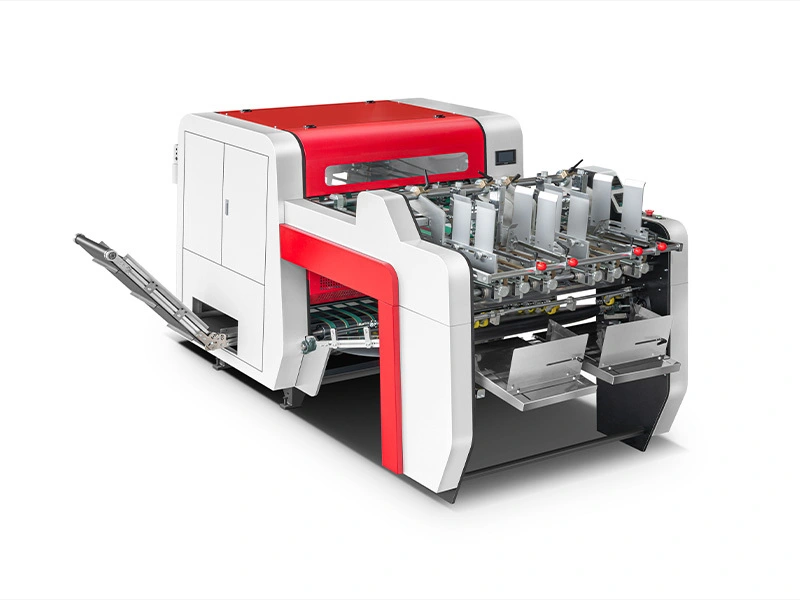

Automatic partial grooving machine Servo automatic adjustment

Advantages

● Magnetic grid digital display for size adjustment

● Side locking tool lever to solve the error of repeated knife changes

● Humanized design of the edge correction adjustment to enhance the adjustment speed.

● Ergonomic take-up for increased operating comfort.

● Double rack and pinion cross-adjustment belt for dead-angle free pressing of the work piece.

Major advantages

● Automatic waste delivery system

● Magnetic grating assisted positioning system

● Partial grooving knife:Servo automatic adjustment

Product details

Technical Parameter

|

Knife Left Right Fine Tuning |

Accuracy0.02mm |

Width Of Work Piece |

100-850mm |

|

Length Of Work Piece |

100-500mm |

Groove Degree |

90°-130°adjustable |

|

Normal Accuracy |

±0.1mm |

Number Of Grooving Knife |

8Magnetic grid positioning knife + 4 servo knife |

|

Thickness Of Work Piece |

200g-2.0mm |

Feeding Type |

Belt friction type |

|

Single Or Double Feeder |

Double feeder |

Scroll Belt |

Move the belt by hand wheel quickly |

|

Waste Material Delivery System |

Automatic waste removal from the side of the machine |

Grooving Angle |

Independent adjustment of each knife head |

|

Knife Sharpener |

2pcsblades sharpen automatically |

Weight |

2000KG |

|

Power |

4.5KW |

Dimension |

2650x1530x1550mm |

|

Best Speed |

30-32m/min(200x200mm)120-150PCS/min |