Сосредоточьтесь на производстве и обслуживании Grooving Machine в течение 28 лет.

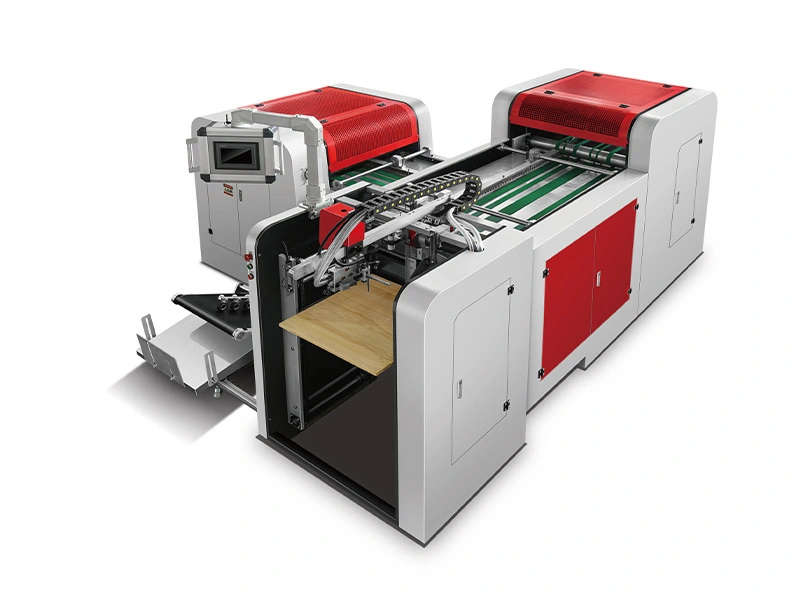

Thin Board Automatic Bidirectional Grooving Machine

Advantages

● Feida feeding (no scratch),solve the problem of paper surface being scratched when the belt divides the sheet.

●

Scroll flipping steering system(no scratch),fast,high stability.

●

Waste discharge: the waste will be delivery out of the machine automatically by dedicated conveyor belt,improve capacity to make the equipment more stable.

●

Automatic collection of finished products:save the finishing time of finished products.

Detalles del producto

Technical Parameter

Material size of 1st step | Length:195-500mm Width:195-500mm | Material size of 2nd step | Length:195-500mm Width :195-500mm |

Max grooving lines of 1st step | 6 lines | Max grooving lines of 2nd step | 6 lines |

Best accuracy | ±0.05mm | Material thickness | ±0.1mm |

Normally accuracy | ±0.1mm | Grooving angle | 90°knife holder used for making 80-110grooving angle 120°knife holder used for making 110-140 grooving angle |

Adjustable angle type | Knife holder can be adjustable independently | Velocidad | 80pcs/min (if size 300*/300mm) |

Quantity of girder | 2 girders(1st step) 2 girders(2nd step) | Quantity of knife row | 3 rows of knife of each grooving part |

Feeding type | Feida air feeding g system | Platform type of adding paper | Upper and lower platform(save time of paper cutting) |

Adjustable scroll belt | Remove the belt quickly by hand wheel | Waste material delivery system | Suction device+side delivery system |

Knife sharpener | Auto knife sharpener | Peso | 3000KG |

Fuerza | 12.5KW | Tamaño de la máquina | 3200*2950*1570mm |

Floor space of machine | 10㎡ | Correction principle of 1st step | Belt correction+steel ball correction |

Correction principle of 2nd step | Belt correction+steel ball correction | Flipping principle | Scroll flipping(flipping scroll) |