no data

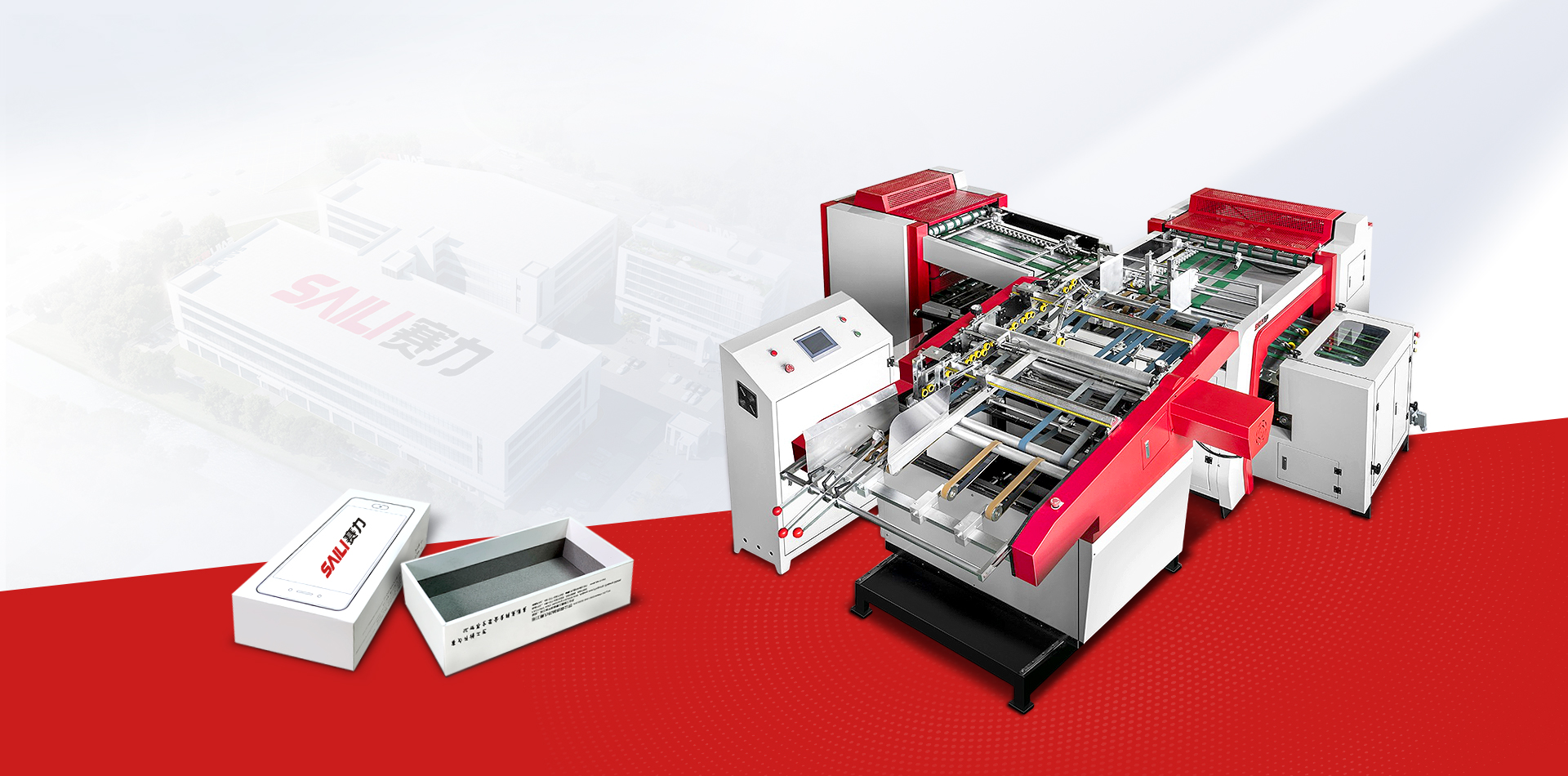

Professional custom Paperboard grooving machine

We have strong R&D team,continuous development and innovation over the past 26 years.

no data

no data

no data

Full scene solution

Grooving Ivory board/gray board /MDF and other materials, Mainly promotion models:

● Corner cutting and grooving machine

● Precision t-shaped grooving machine

● High efficiency bidirectional grooving machine

● Customized blade research and development

● Grooving process training

● Knife version design support

Three reasons to choose us

no data

About Zhejiang Saili Machinery

Zhejiang Saili Machinery CO.,LTD is one of a professional manufacturer and exporter of grooving machine, slitting machine, magnet sticking machine, box making machine & packaging machinery in China. Our company is located in Wenzhou City, covering an area of 6,280 square meters, with a building area of 2,800 square meters.

With 50-million-worth fixed assets, we employ over 210 personnel, including 50-60 professional technical talents and 3 senior engineers.

Packaging equipment, we sincerely hope we can be your best choice partner in China! Let's work together to be more success tomorrow!

Application scenarios solution

Grooving making packaging box more beautiful, Application Solution High-end gift box/Ecological product/ Mooncake box and so on

no data

News with impact.

There is nothing better, right?

no data

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Ready to work with us?

no data

Copyright © 2025 SAILI MACHINE |Sitemap | privacy policy